What you’re looking at is a Pinion tandem bicycle that uses an 18-speed gearbox that’s been mounted between two cranksets. It has three belts connecting everything up!

It took me some time to work out why it was built this way – and in this article, I’ll be explaining it all.

This highly unusual bicycle was built by one of the most well-renowned tandem builders in the world, Co-Motion Cycles. This North American manufacturer has been busy hand-building bikes since the 1980s, and I actually once commissioned them to build a fully belt-driven tandem that I rode from Europe to Australia.

Ok, so why has the Pinion gearbox been separated from the cranksets on this bicycle? To understand, we need to learn a bit about how both Pinion gearboxes and tandem bicycles work.

Let’s start with the Pinion gearbox.

Understanding Pinion Gearboxes

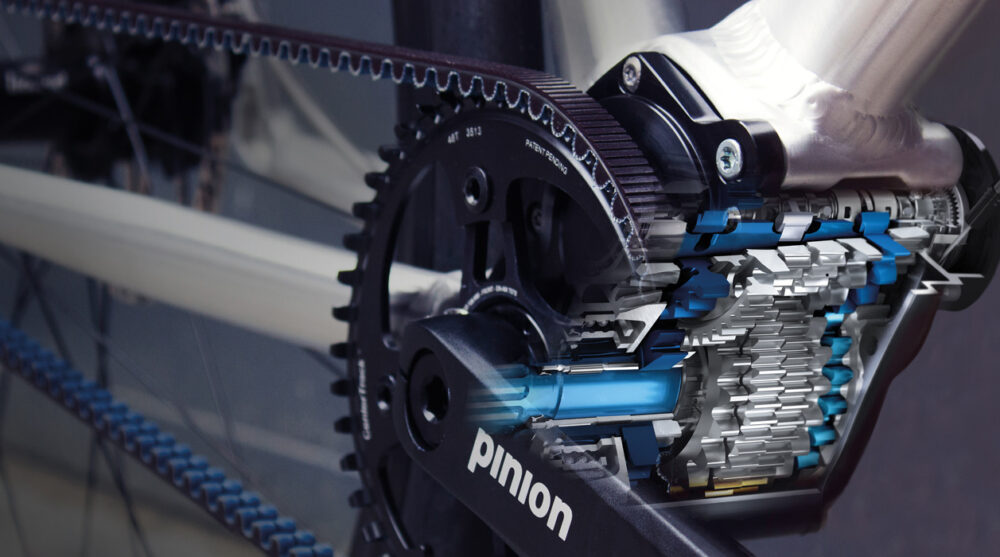

What you’re looking at is an 18-speed Pinion bicycle gearbox. This is not dissimilar to gearboxes found in other industries, in fact, the designers of this gearbox are former Porsche automotive engineers.

Compared to derailleurs, Pinion gearboxes are less susceptible to damage, they don’t require any tuning or adjustment, they don’t wear out, and you can change gears any time. There is very little cleaning too – the only maintenance is the 10,000km oil change which takes no more than 15 minutes to complete.

The thing you need to know about these gearboxes is that, unlike a normal drivetrain, the drive sprocket moves at a different speed to the crankset and the speed varies depending on the gear selected.

In the first gear, the cranks rotate almost twice as fast as the drive sprocket (1 to 0.55). And in the 18th gear, the sprocket rotates significantly faster than the cranks (1 to 3.45).

Ok, so the changing sprocket speed is the first thing you need to remember. Let’s now discuss tandem bicycles.

Understanding Tandem Bicycles

Tandems use a timing belt or chain that links up the pedal speed of the front and rear riders. The sprockets of a timing gear are usually the same size, which keeps the front and rear cyclists pedalling at the same RPM.

The advantage of pedalling in-phase is that it’s easier to take off from stationary, it’s great for balancing, and both sets of pedals can stay up high when cornering.

But it’s worth noting that some tandemists do like to have their cranks out of phase, which can help eliminate the ‘dead spot’ in the pedal stroke. By setting the crank arms 90 degrees out there will always be one rider in the power phase.

Why This Pinion Tandem Drivetrain Has Three Belts

Knowing that the Pinion drive sprocket rotates at different speeds in different gears, it’s clear we cannot just connect this sprocket to another crankset like normal.

If we did, one rider would be pedalling at a vastly different cadence.

To get around this, Co-Motion has installed a typical timing gear on the non-drive side of their Pinion tandem with a 1:1 ratio.

The combined power of the riders is then fed into the gearbox using the first drive side belt. This belt essentially replicates what a Pinion crank arm does – feeding pedal power into the gearbox for a change in gear ratio.

Our last belt then sends the pedal power from the gearbox to the rear wheel just like normal.

After cracking the code of this bizarre drivetrain, it left me wondering why we don’t just put the Pinion gearbox at the rear cyclist’s crankset, and mount a second timing sprocket to the crank axle?

It turned out I wasn’t the first person to have this thought…

Campmajo’s Pinion Tandem Solution

Spanish custom bicycle builder, Campmajo, has built a few tandems with a Pinion gearbox at the rear crankset.

Campmajo machines a special sprocket spider that clamps firmly to the crank axle so that it can rotate at the same speed as the Pinion cranks. This allows for a 1:1 timing gear with the second crankset.

The issue with this setup is that it requires the drive side crank arm to be machined down to make space for the spider. But Campmajo has assured me they’ve extensively tested their modification and are so confident of its strength that they provide a 5-year warranty on it. The great news is that Pinion will still honour the factory warranty on the rest.

One downside to Campmajo’s design is that it might not be wide enough to fit two belt sprockets. This then had me wondering if it was possible to move the timing sprocket to the other side of the gearbox axle, and lo and behold, someone had already thought of that too.

Belt Bikes’ Pinion Tandem Solution

Dutch bike manufacturer Belt Bikes have created their own tandem crank arms for Pinion gearboxes. This has allowed them to build a sprocket spider into the left crank arm for a belt drive timing gear.

This is a super neat solution, however, the downside is that the q-factor – or distance between the crank arms – has been increased by 40mm to accommodate the new spider. This change in dimension could potentially result in knee-related pain for some riders, but it’s worth noting this is still 25mm narrower than many fat bike cranksets.

Summary

What started as an article describing a quirky Pinion tandem drivetrain took me down a rabbit hole of bikes and products I never knew existed.

It’s cool to see the custom bike community finding ways to fit Pinion gearboxes on tandems. While Co-Motion’s triple belt drivetrain is an interesting solution to the problem, if it were me, I’d be opting for the more simplified Campmajo spider and modified crank arm, or Belt Bikes Pinion tandem crankset.